Services for gas filling systems

All from one source

For customers’ requests, technical advice as well as project management we are at your disposal with a multilingual team. Being producers of complete systems, we would appreciate if you contacted us concerning questions on all components mounted in our systems. No matter where you set up our products – our service takes care on a worldwide basis as our engagement continues after having sold our products.

Our service concept comprises the following activities:

Technical advice

M-tech has numerous international business relations around the globe. Our international team accompanies each customer from the beginning on to always find the best solution. Of course, we also analyze your situation on site and adapt each detail of our gas filling systems according to your needs. Our core competence is the production of fully-automated as well as semi-automated systems.

Whenever you have questions about our products or need technical information, we will be happy to help you.

Product training

M-tech delivers German competence into the entire world. Our demand is the constant reliability and maximum performance of our products. To be able to fulfill these requirements at any time and any place, we offer product trainings for our valves. In doing so, your personnel on site will be able to ensure a perfect working of your filling system. This increases the number of switching cycles and maintains the reliability of your equipment.

The valve training takes place at our head office or directly at the customer’s filling plant. Many of our customers make use of our valve training in the course of an on-site maintenance.

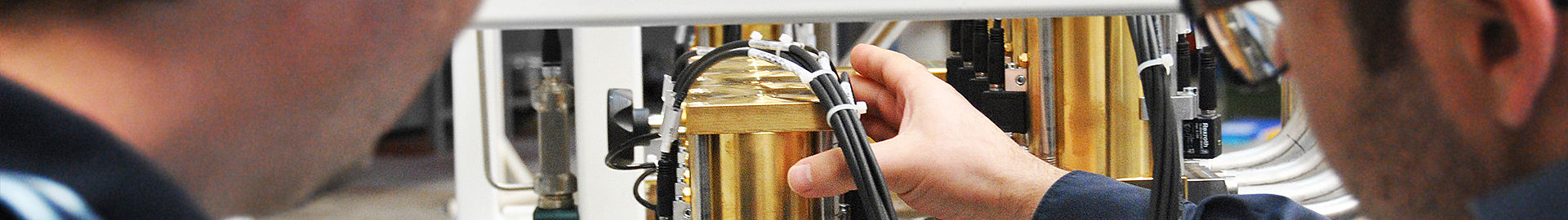

Commissioning of the filling system

We offer our customers to send an experienced m-tech technician to accompany the first commissioning of the filling system by giving active support and technical advice for daily usage. This service lets you experience the maximum performance and disposition at any time.

Repair

m-tech valves are outstanding and used in extreme applications. In case you should have problems with one of our valves, you can return it to us anytime. We quickly analyze the valve and send you a detailed repair report. As soon as your valve is repaired and ready for operation, it will be returned to your filling plant.

Downloads

Return form pdf / 54,8 KB

Complete maintenance

Special and extreme requirements leave their marks also on high-quality products. For this reason, m-tech recommends a complete maintenance of your filling system after a period of around 5 years or 50000 switching cycles. As seals and material are exposed to natural wearing, it is extremely important to professionally maintain your gas filling system at regular intervals in order to guarantee the safety of your personnel as well as a correct production process. Our experienced technicians who also build new filling equipment in our facilities come to your site to maintain your filling system completely. This includes the exchange of all seals and cleaning of all components for oxygen service with our mobile ultrasonic cleaning system. Thus, your filling system will be completely overhauled within a period of 1-2 days.

This gives you planning reliability for the coming years and permanently ensures maximum efficiency.

Modification

Has your system reached the capacity limit? Do you need another gas inlet, a recalibration of your pressure relief valve MPG 12 RV or a further ramp outlet?

m-tech systems grow in line with your requirements. Please get in touch with us. We deliver you the suitable modification.